ELECTRIC POWERTRAIN DEVELOPMENT

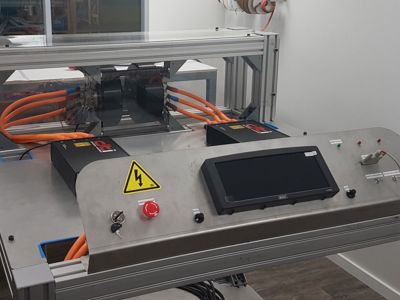

Our specialized engineering group is capable of developing custom electrical powertrain solutions tailored for each customer’s needs. Bringing all the components together in order to make a full fledge functional electric vehicle is at the core of ADESS AG’s EV powertrain department.

ADESS AG’s wide experience with composite materials allows the development of compact and race spec lightweight battery packs while maintaining all necessary safety requirements thanks to FEA (Finite Element Analysis). Full custom solutions going from latest technology cell choice, electronics integration to cooling system are made available considering each type of vehicle and customer’s needs.

Off the shelf components are selected for quick and efficient prototyping, custom harnessing systems, both High and Low voltage, are designed and integrated following the most rigorous motorsport standards in order to interconnect each system. Furthermore, software solutions are provided in order to maximize vehicle functionality and tunning capability.

High Voltage Battery Design:

- Concept Layout

- Cell testing and selection

- Detailed design (CATIA V5/Visio/Altium Designer)

- Battery Management System Integration

- Structural mechanics and analysis (FEA)

- Custom cooling solution using CFD analysis

- In-house Battery manufacturing

Motor and Motor Control:

- Off the shelf motor and inverter selection

- Gear box design

- Custom cooling solution

- HV harnessing design

- Testing Communication and calibration

Low voltage Electronics and Software:

- Software and controls architecture and integration

- Low voltage race spec harnessing design and manufacture

- Off the shelf electronics system integration: lights, sensors, control units

- Pilot custom Infotainment systems

- Data-acquisition